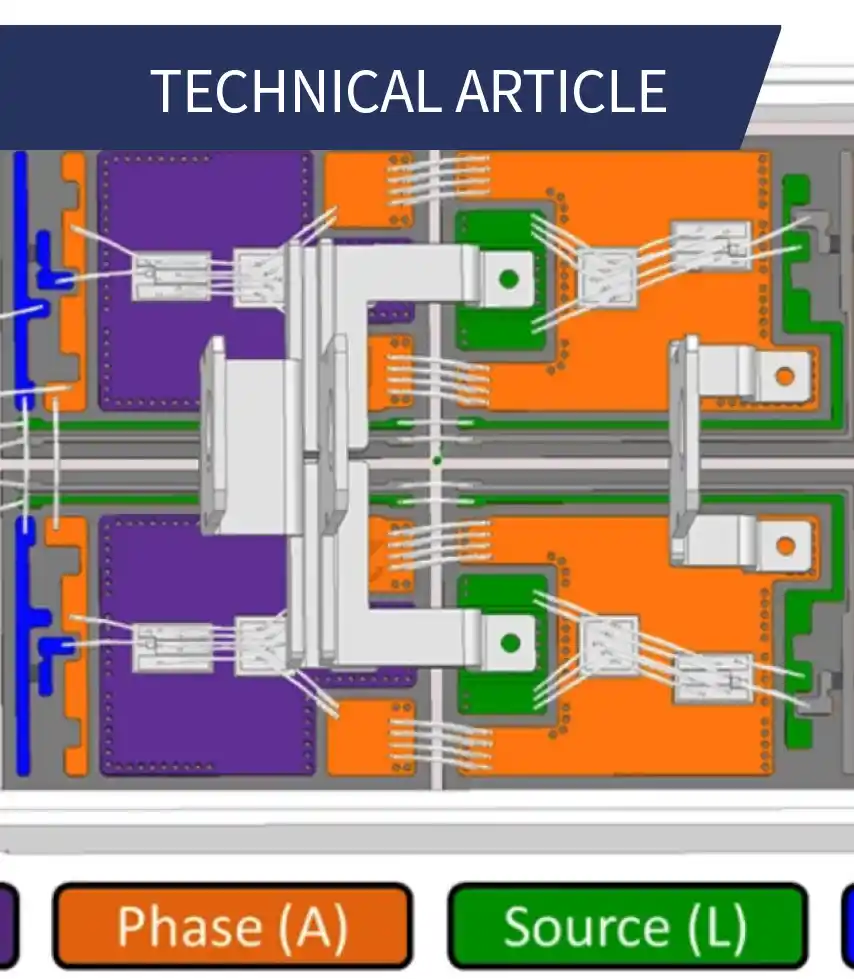

Silicon Carbide (SiC) technology has shown performance improvements over traditional silicon (Si) components across the board, including lower power losses, faster switching, higher operating temperatures, greater power density, and overall higher efficiency.

Wolfspeed’s upgraded portfolio of power modules can provide these advantages in industry-standard footprints with configurations that serve a variety of applications while also helping to bridge the power continuum between lower-power, discrete-based applications through industry standard footprints and optimized footprints in high power modules. This article will demonstrate how designers can increase system efficiency while lowering cost but most importantly, greatly increase the overall reliability system-wide.

Related Content

Energy & Power Technical Articles

Wolfspeed Top-Side Cooled SiC MOSFET

Top-side cooled power semiconductors are gaining interest across the power electronics design community. Improved thermal…

January 22, 2025

Energy & Power Technical Articles

Power Modules: One Shortcut to EMI Compliance

Electronic devices that are in proximity or share common conductors are susceptible to electromagnetic interference (EMI)…

December 21, 2024

Energy & Power Technical Articles

Benefits of Designing with Wolfspeed Silicon Carbide in Low Voltage Motor Drives

Silicon carbide is enabling a global shift to embedded industrial low voltage motor drives where the drive and motor are combined into one unit, resulting in…

September 19, 2024